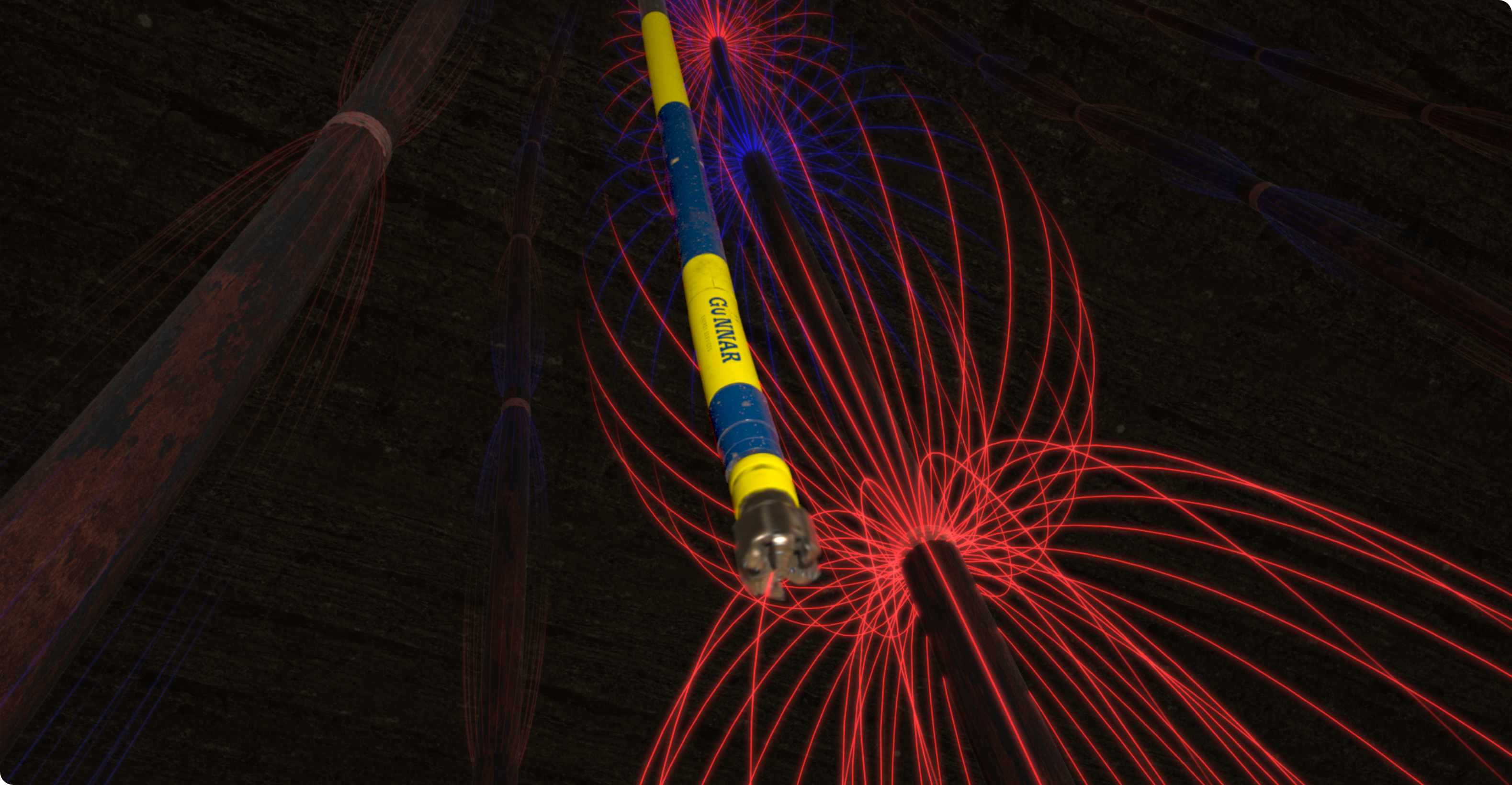

Casing magnetization service that compliments Gunnar’s EverReady™ passive magnetic ranging service

A cost-effective solution, MaxWell™ increases the detectable range of downhole casing via Gunnar’s EverReady™ and other passive magnetic ranging (PMR) methods.

Magnetization allows for detection in difficult environments such as extensive salt formations where traditional active ranging methods can be ineffective.

MaxWell™ resolves many issues by magnetically aligning casing to remove magnetic inconsistency. This inconsistency is a result of the random distribution of magnetic domains during the casing manufacturing process. MaxWell™ eliminates this inconsistency and allows for the detection at maximum ranges.

Wellbore Intersection

This is the process of intentionally connecting two wellbores. The MaxWell™ technique complimented with MWD/Passive Magnetic Ranging can be used to accurately locate the target wellbore and ensure a safe and successful intersection.

Plug And Abandonment

This is the process of permanently closing a well. MaxWell™ can be used to locate the wellhead and ensure that the plug is properly placed.

Fishing Operations

This is the process of retrieving a lost or damaged object from a wellbore. MaxWell™ can be used to locate the object and safely retrieve it.

Increased detection range and accuracy

The magnetization process can enhance the signal from the casing by up to 2X. This means that EverReadyTM can detect the casing at a greater distance and with greater accuracy.

No special handling procedures

There are no special handling procedures required for the newly magnetized pipe. It can be handled and installed in the same way as any other casing.

Long-lasting magnetism

The magnetization process lasts for years. This means that the casing can be magnetized once and then used for multiple drilling operations.

- SAGD

- Wellbore intercept

- Relief well intercept and dynamic kill

- Plug and abandonment intercept

- Open hole re-entry below a fish

- Relative Wellbore Spacing

- Collision avoidance

- Wellbore twinning for solution mining